Wireless Sensors System for Gas Concentration Monitoring

Automated system for long-term autonomous monitoring of the gas concentration level involving the use of high sensitivity gas sensors and data acquisition, processing, and transmission system.

Task

Taking into account the mainstreaming of gas sensors at gas facilities objects to monitor the environment and leaks, it was required to develop a cost-effective, easy-to-install and maintain solution, ensure its long-term operation and complete monitoring automation.

To design a system of highly sensitive autonomous sensors of industrial and biological gases (including methane, ethane, carbon dioxide, and carbon monoxide), the competencies of the Graduate School of Physics and Materials Technology of the Institute of Machinery, Materials, and Transport (IMMT) of SPbPU, the Laboratory of Industrial Systems for Streaming Data Processing of the SPbPU NTI Center, and Microsensor Technology LLC staff were combined.

The task of the GSPMT IMMT SPbPU was to design sensors with microlenses based on low-melting chalcogenide glass, which are applied to the surface of infrared (IR) light-emitting diodes and light detectors. As a part of the study, compositions of chalcogenide glass with a set of the following unique physicochemical properties were developed: a wide range of spectral transparency, a low transition temperature to a viscous state, weatherability, a good adhesion to the semiconductor chip surface.

The ISSDP Laboratory specialists has developed a system for gas sensors data acquisition and processing, as well as a data transmission system over wireless networks.

Solution

The sensors system under development combines the scientific activity results of semiconductor physics, instrumentation, optical materials science, and data streaming technologies.

Data acquisition and transmission system

The ISSDP Laboratory experts also designed the system structure that performs wireless data acquisition and processing from a sensors set. The system is a set of sensors located in the crucial equipment nodes or throughout the entire room, and transmitting measurement data through the gateway of a low-consumption local wireless network.

The gateway software allows the following functions:

- Gas sensors data acquisition via the LRWPAN wireless network in the transmitting unprocessed data and only primary characteristics (i.e. data aggregation results directly on the sensor) modes.

- Managing the sensors wireless network, ensuring the connection of new sensors, monitoring their operation, transmitting configuration data, remotely updating sensors software.

- Transmitting data to the information system.

The software prototype is at the final stage of adjustments. The latest test results have confirmed the correct operation of data transmission channels.

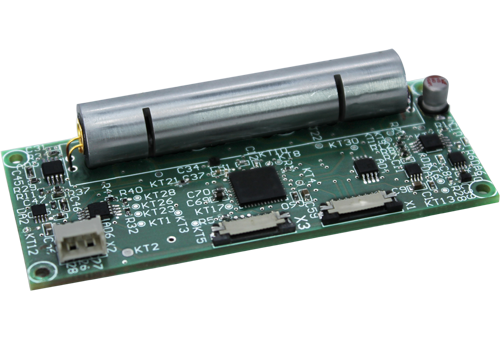

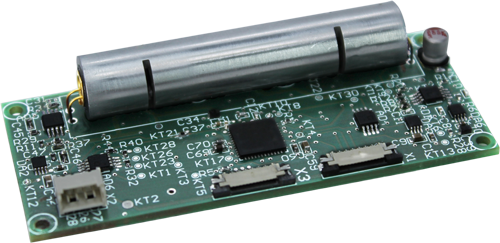

MDS-4-2 gas sensor

Optical unit

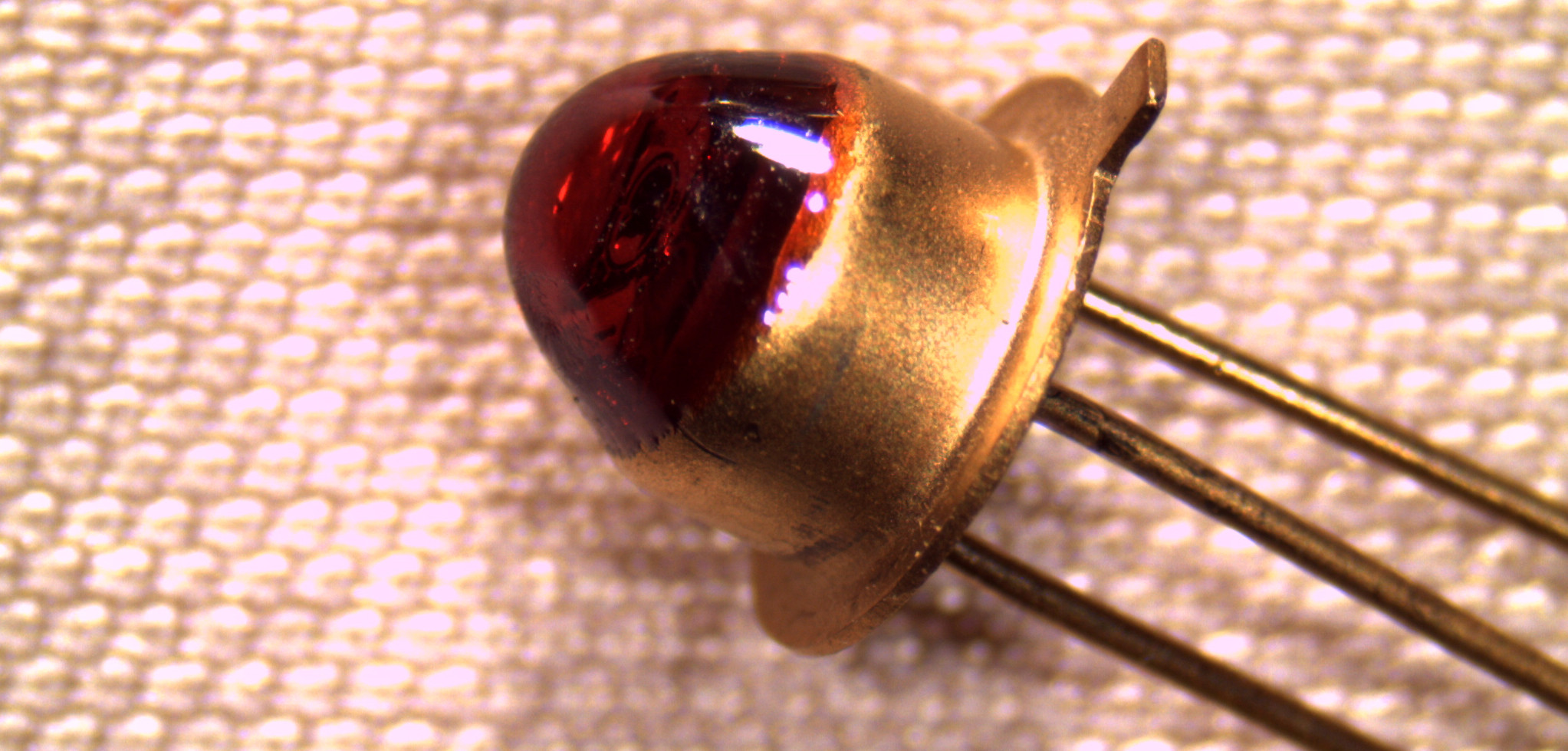

The optical sensor unit was implemented by the staff of the Graduate School of Physics and Materials Technology of IMMIT SPbPU with the application of infrared (IR) light-emitting diodes and light detectors, on the surface of which microlenses of low-melting chalcogenide glass are applied using the developed technology. Since the appreciable concentration of gases depends on the efficiency of collecting emission on the light detector, the focusing microlenses system development can significantly improve the characteristics of the device.

Chalcogenide glass with the necessary physicochemical characteristics (refractive index, spectral transmission range, glass transition and melting temperature, adhesion level, chemical weatherability) synthesis was a special materials science task, the solution of which made it possible to increase the minimum gas concentration detected by sensors by 3-5 times.

An IR LED with a chalcogenide microlens applied

Advantages

Taking into account the mainstreaming of gas sensors at gas facilities objects to monitor the environment and leaks, this development has a high commercial potential due to low energy consumption (a long period between mandatory sensor maintenance) and a low detection threshold (<500 parts per million).

Details

Data acquisition and transmission system

Specialized LRWPAN wireless communication standards were selected to implement a low-consumption sensor system with stable periodic data transmission. These standards provide a long transmission range and high energy efficiency (i.e. the transmitted volume of useful data to the energy consumed ratio).

A wireless network crucial feature is the frequency used. The frequency of 868 MHz was chosen for the system implementation, since it provides a higher bandwidth than 433MHz. This is required for the transmission of the unprocessed data. It is also possible to use smaller antennas for such frequency level, which is important for the limited dimensions of the sensors.

Sensors are integrated into a wireless data transmission network via the LRWPAN network. Gas sensors data acquisition, transmission to the information system and control of the wireless sensor network is carried out through the LRWPAN gateway.

When a new sensor is connected, the gateway publishes an up-to-date list of sensors connected to it. It also regularly publishes protocols reflecting its current state. The gateway reports the timestamp, its identifier, OS operating time, process running time, number of sensors, data transmission error counter, amount of RAM used, and a list of active sensors.

Thus, several gateways can simultaneously connect to one server, each of which has several sensors connected to it. At the same time, it is clear to the subscriber from which sensor each value was received.

The user can replace the firmware on the sensors remotely. Through the graphical user interface, the user sends a firmware update command to the server. This command includes the file name of the firmware required. After receiving the command, the gateway checks the firmware version on each of the sensors and updates it, if necessary, via a wireless LRWPAN channel.

To view and analyze data, a Python-written software is used. It is cross-platform and has a graphical user interface. It allows to remotely view all the sensors status and display the captured data in the graph, also simultaneously and independently from several personal computers.

Machine learning techniques are applied to clear the sensor signal.

Optical unit

The sensors use microlenses based on low-melting chalcogenide glass, which are applied to the surface of infrared (IR) light-emitting diodes and light detectors. The researchers developed the compositions of chalcogenide glasses with a set of unique physicochemical properties, including:

- wide range of spectral transparency,

- a low transition temperature to a viscous state,

- weatherability,

- a good adhesion to the semiconductor chip surface.

The physical mechanism of these sensors operation is based on the absorption spectroscopy, where various gases, including atmospheric gases, can act as absorbing agents. The emission/absorption spectral region of a semiconductor opto-isolator determines the types of detected gases, such as methane and ethane (3.20-3.45 microns), carbon dioxide and carbon monoxide (4.20-4.80 microns), nitrogen dioxide (3.40-3.45 microns), ammonia (2.85-3.15 microns), etc. This technology allows to increase the external quantum output of the IR opto-isolator by 5-10 times.

The GSPMT IMMT SPbPU team is developing a unique technology for encapsulating microlenses of a strictly defined shape using computer vision tools and a neural network. Microsensor LLC enters the technology mass production to meet the customer's specifications.

Technologies

| Software programming languages and frameworks: | C, Python |

| Library: | SimpleLink SDK |

| OS: | Linux, TI-RTOS |

| Messaging protocols: | Mqtt, IT 15.4 Stack |

| MCU: | SimpleLink |

Intellectual Property

The research is supported by Project 5-100 at Peter the Great St. Petersburg Polytechnic University "Development of biofunctional glassy and composite materials for wearable electronics sensors"

Project team

- Project Lead: Semencha A.V., Director of GSPMT IMMT SPbPU

- Project Manager: Ovsyannikova A.K.

- Lead Engineer: A.E. Doynikov

- Programmer: N.S. Makarevich

- Technician: Kamyansky D.V.