Hardware and software complex for detecting and classifying fabric faults

Hardware and software complex for fabric faults automatic detection and classification in the textile industry based on computer vision and AI technologies.

Task

Currently, the grade determination and the detection of textile materials defects is one of the least computer-aided stages of the manufacturing chain in textile and light industries. In most cases, manual labor is used, so dozens of people are employed in quality control units, and an immense amount of working time is wasted. Such measures are not always cost-effective. Faulty goods can be overlooked. Products quality improvement is one of the textile and light industries overarching priorities.

For automated quality control of rolled materials, such as fabric, paper, plastics, etc., it is urgent to create an automated defect detection system (or automated quality control system – AQCS), which would be a part of an automated process control system. With timely analysis of the entire flow of defects in textile and raw materials, this will significantly boost textile factories performance.

However, the wide use of such automatic visual information processing systems in the textile industry, as well as in other national economy sectors, is constrained by a number of factors, such as massive information flows within signal processing systems, the need to develop special methods and means for detecting defect signals with a low signal-to-noise ratio, the high cost of quality control systems available, high speed of changing fabric patterns requiring system reconfiguration.

The project team of specialists from SPbPU, HSE University, ISPU, and VIZIUMTEKS LLC task was to create a software and hardware complex involving the use of computer vision and machine learning techniques will have a number of key advantages over textile manufacturing foreign counterparts, which include:

- Fabric faults up to 1 mm in size detection;

- The expected cost of the complex is from 3 to 6 million rubles (while the foreign counterparts price varies from $100,000 to $650,000).

Solution

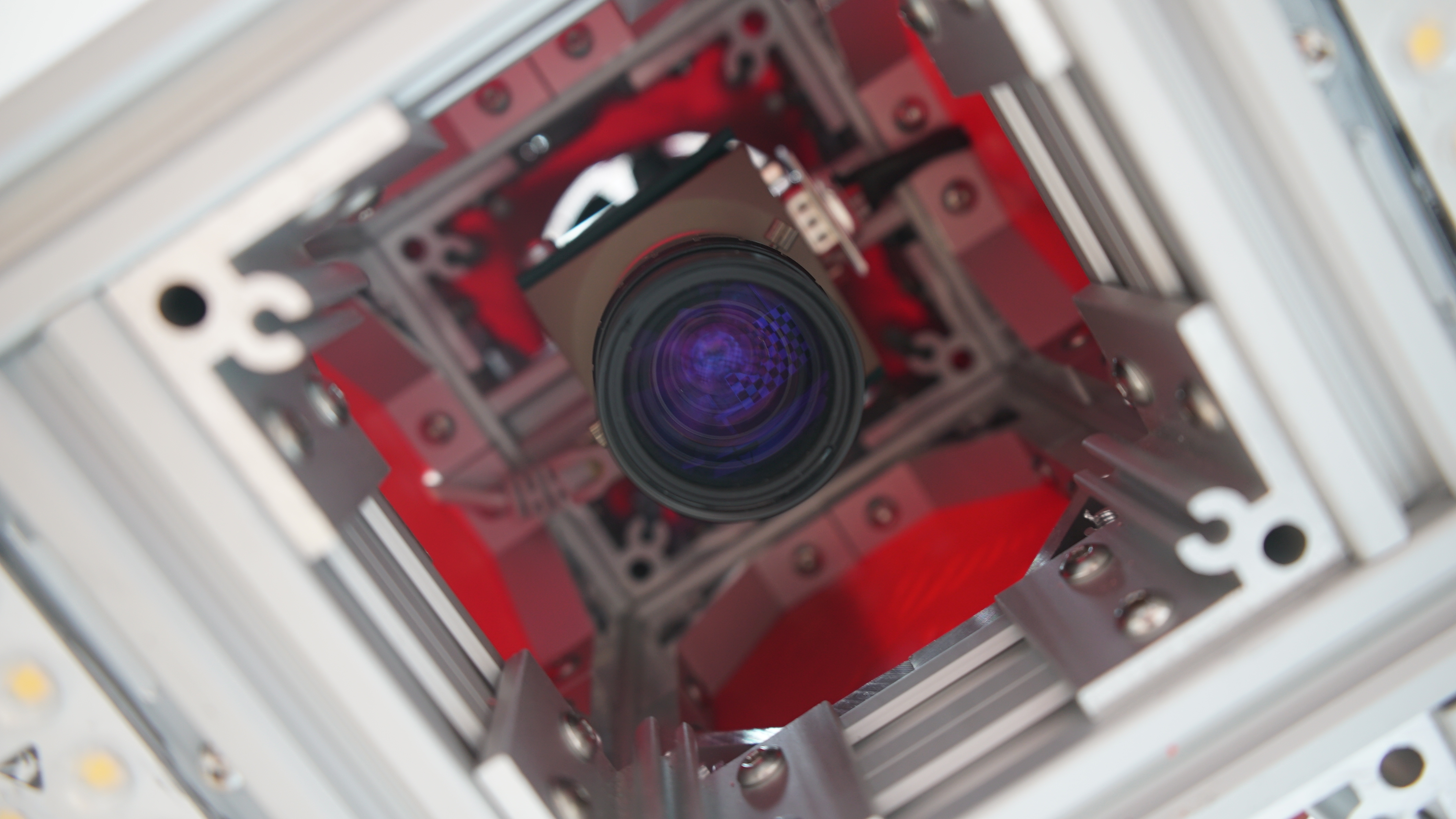

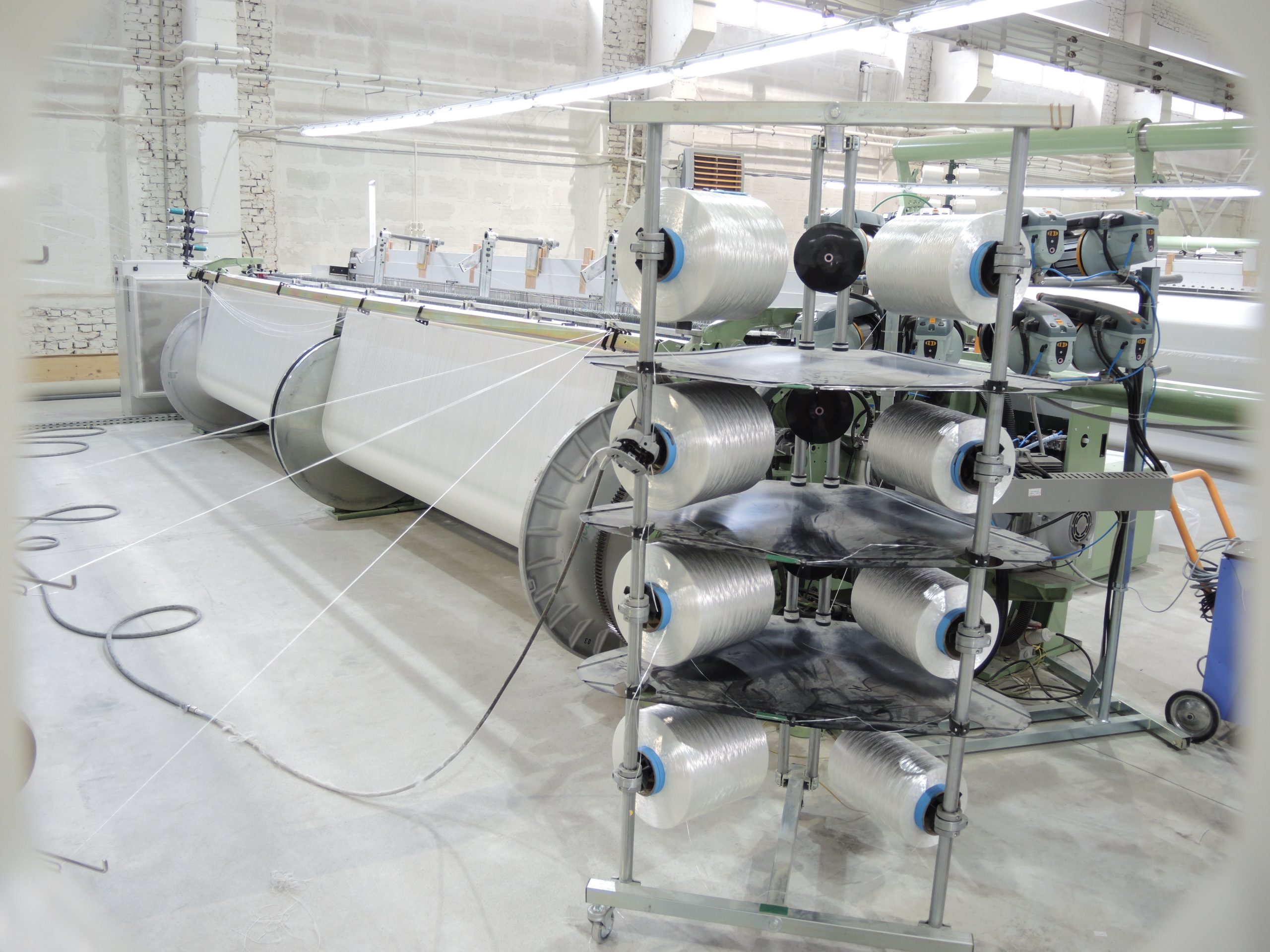

A prototype of a hardware and software complex (HSC) for automated detection and classification of fabric faults in textile manufacturing has been developed. The hardware and software complex consists of image capture modules (digital cameras and lenses, lighting devices), an image processing and storage module, and a synchronization and control module. Neural network algorithms for detecting, localizing, and classifying defects are pivotal in the image processing software module. The software implementation uses a deep convolutional neural network for semantic segmentation of images. For machine learning, a database of defects in plain weave materials after primary finishing, which includes more than 150,000 fabric samples provided by textile enterprises of the Ivanovo region, was prepared. The developed system detects, classifies defects, and generates an output signal with information about them. Thus, the production operator can quickly respond to the identified defect, determine the cause and place of its occurrence, and transmit information to the production site responsible for this defect. Test results From May to December 2022, the HSC underwent pilot operation on the manufacturing line of the Teikovo Cotton Mill (Ivanovo region). When testing the hardware and software complex on a 700 m long fabric sample, the system detected 1,363 defects of 17 types, most typical for canvases that have undergone bleaching operations. To determine the degree of defect detection accuracy, the fabric sample was then sent for manual disassembly to the enterprise quality control department, where 217 defects were detected. Thus, with the help of the HSC, 6.28 times more defects were detected, since the system with high accuracy detects even minor flaws that are invisible to the eye when rewinding the material at a speed of up to 60 meters per minute. In the future, it is also possible to increase the speed of defect detection. The information about the identified types of defects accumulates in the computer memory during manufacturing. This data can be requested by the operator at any time. The necessary information can be given both about a specific cloth roll and throughout the entire batch. If the canvas critically deviates from the standard that is preconfigured, the PC operator will receive a warning message with a sound or light signal. When integrating the operator's computer into the factory IT infrastructure, it will be possible to supervise all the images received in real time from any local network PC. This will allow employees of other services to remotely monitor the quality of the produced canvas.Applications

Hardware and software complex is expected to be used to handle the record (capturing specific quality data) and analysis (comparing the results obtained with reference ones).

The complex designed can be applied at the following stages of textile production:

- Quality control of the huck at the exit of the machine (since the complex can be installed on the loom);

- Quality control of bleached huck before the printing process;

- Print quality control directly at the exit of the printing machine;

- Material quality control after finishing;

- Materials input control and control at the preparatory stage for the cutting in garment factories.

Technologies

| Libraries and frameworks: | OpenCV, PyTorch, TensorFlow, CUDA, libpng |

| Software programming languages: | Python, C++ |

| OS: | Linux |

| Architectures: | x64, ARM |

| CVS: | Git (GitLab) |

Intellectual Property

Publications

The research is funded by the Foundation for Assistance to Small Innovative Enterprises in Science and Technology (FASIE)

Project team

Project manager: A.V. Lodyshkin, Associate Professor at HSE University, CEO of VIZIUMTEKS LLC

Chief Scientist: T.Y. Kareva, Doctor of Technical Sciences, Professor at ISPU

Head of the hardware and software development direction: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory, NTI Center, SPbPU